- Main /

- Production and Technology /

- Manufacturing /

- Сontract PCB assembly /

- SMD assembly

PCB surface mounting / SMD - mounting |

|

|

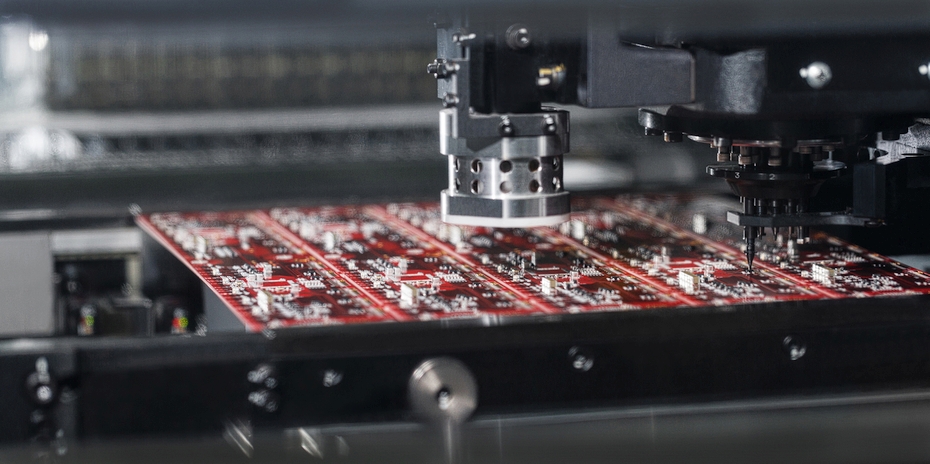

Pacific Microelectronics offers on the Russian market all kinds of services for manufacturing of printed circuit boards and mounting of electronic components.

Developed infrastructure and modern equipment allow our company to carry out surface mounting of electronic components (or SMD - mounting) on printed circuit boards in any volumes and in the shortest terms. Our fleet of high-speed installers has about fifty machines able to perform surface mounting of printed circuit boards at a rate one element per 0.06 seconds, and each SMD-line mounts over a million components per day. We use only high quality soldering equipment and screen process printers of exclusively Japanese manufacturers whose age does not exceed three years. This means only one thing - our mounting manufacturing is fully compliant with the latest achievements of electronic industry and enables fast and, most importantly, efficient fulfillment of orders of any complexity in time. We always provide our customers an absolute guarantee of quality for mounting of printed circuit boards as well as quality of the components installed by us. Our company takes orders of any complexity. All the products without exception are subjected to a strict final inspection - a standard test is performed for quality of soldering, and if necessary, a functional test is performed if the customer has an appropriate program or testing methodology. All of the above events completely exclude supply of defective or poor quality products to our customers and partners. We attentively observe our assembly lines to comply with all principles and requirements of RoHS for support of lead-free technologies.

Advantages of PCB surface mountingOne of the main advantages of surface mounting (SMD) is its efficiency. The use of modern, fully automated equipment allows us to produce cost-effectively electronic modules in large quantities. Before mounting, there is no need to make special preparation of leads and other manipulations: all this is done automatically. Application of surface mounting may significantly reduce size and weight of PCB due to denser routing, layout and use of components of small dimensions. The boards mounted in this way considered to be more repairable. Reduction of length of leads and density of PCB layout provides improved quality of transmission of HF and weak signals.

Briefly about prices for services providedSurface mounting is one of the profile activities of Pacific Microelectronics. Quality of our SMD-mounting meets the highest requirements of modern technologies. However, with such a high level of quality of services provided to date, we are able to maintain the lowest and competitive prices at electronics market. Our company founded in 1985 is one of leaders at market of contract assembling in Russia due to high quality of the products and low prices. In addition, our employees are all without exception experts of the highest category, perfect masters of their specialty. The company has a flexible pricing system, and we offer discounts and special conditions for repeated and long-term orders for our regular customers and partners. Over the years, we established successful and long-term relations with wholesale customers with whom we cooperate only on a mutually beneficial basis.

|

|