- Main /

- Production and Technology /

- Manufacturing /

- Сontract PCB assembly /

- DIP assembly

DIP mounting / output mounting |

|

|

Pacific Microelectronics takes various orders for PCB mounting. One of the main advantages of our company is an individual approach to each project and the use of modern equipment for various types of mounting.

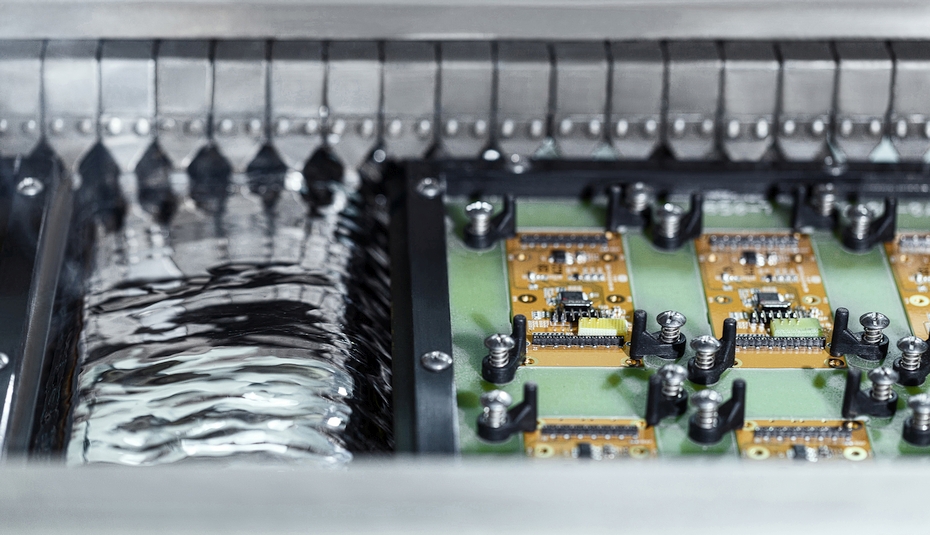

We perform mounting of any DIP-components in lead-out packages, components with axial and radial leads, non-standard and large-size components and connectors. We have automatic installers of DIP-components which eliminate the possibility of installation of an element with incorrect nominal value or polarity. Depending on design of the customer's project and order volumes we use various technologies and equipment under DIP-mounting / output mounting of components. Under serial volumes of order, selective soldering system is used providing selective soldering of individual components without heating of the entire board.

This technology provides high quality DIP-mounting under high performance. Section of component installation conveyor using automatic molding and lead trimming followed by wave soldering is used for experimental and medium-size series. Pacific Microelectronics carries out a multi-stage quality control at all stages of assembling of electronic modules. Under such conditions, we can offer you the best terms and prices with 100% quality of the products. |

|