- Main /

- Production and Technology /

- Technologies /

- Organization of production

Manufacturing management

|

|

|

|

|

Pacific Microelectronics provides a full range of services in the field of manufacturing of any electronic devices. We carry out contract performance of turnkey projects. Due to a combination of various stages of manufacturing we are able to minimize final cost of the products. Manufacturing preparationThis stage is necessary for providing of technological readiness of production facilities for manufacturing of the products according to customer requirements. It includes:

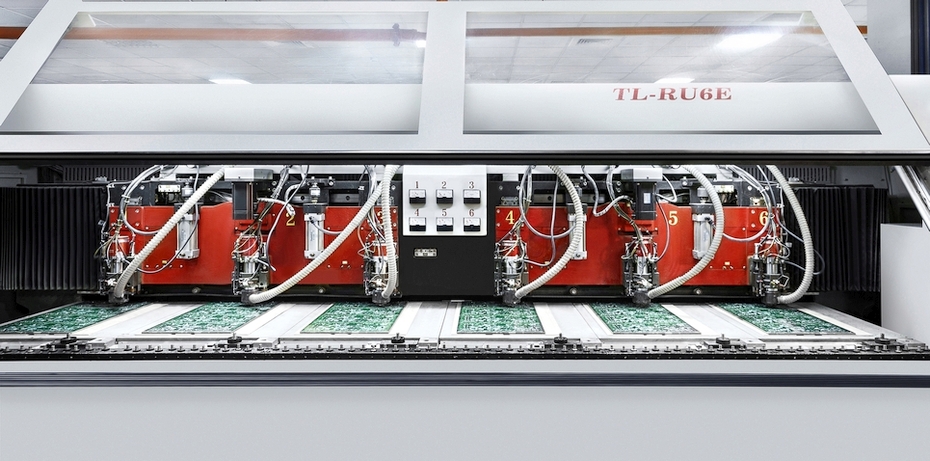

From the moment of processing of the request and calculation of the order, our specialists begin close interaction with the customer. We provide design study including a thorough analysis of the project for errors. The next stage is agreement on the order price. Price of the product depends on its complexity, volume of the order. We buy components in large batches that reduces cost of our products and gives opportunity to conduct pricing policy beneficial to our partners. Technological preparation of the order implies preparation of the files in full compliance with requirements of the manufacturing equipment. We analyze manufacturability of the project to ensure high quality of the manufacturing. To confirm the correctness and quality of the assembling we produce prototypes of PCB and electronic modules before start of serial manufacturing. ManufacturingTechnological capabilities of manufacturing facilities of Pacific Microelectronics provide manufacturing of printed circuit boards and electronic modules in strict accordance with modern requirements to electronics, as evidenced by certificates. Manufacturing of products is carried out on automated lines of the last generation. The technology has been brought to perfection. In the process of manufacturing, strict quality control, checks for compliance with key performance indicators are performed. The following control methods are used:

In addition, input control of materials supplied to manufacturing sites is performed. DeliveryProducts which passed quality control are packed with the use of various materials including anti-static ones to provide effective protection from adverse external influences. We carry out delivery by any transport in accordance with the client's requirements to terms and budget. The company provides prompt delivery of pilot samples and orders through a well-established logistics system. We use effectively delivery tracking that is a excellent way to control delivery terms. Combination of different methods of delivery allows to guarantee optimal terms of delivery. Standard term of delivery of PCB is 2-3 weeks. In case of urgent order, it is 1 week from the moment of confirmation of the order till receipt of the product on warehouse. One of the advantages of our company is attentive work with claims in which we objectively assess the situation and solve the problem in the best way for the customer. |

We perform contract manufacturing

|